|

Bespoke

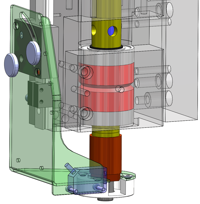

CNC Machine Bespoke

CNC Machine

Automated, clean

room machining of surgical implants.

"Oliver provided engineering and design to Orthomimetics for

several years, on projects ranging from development of

reusable arthroscopic medical devices to bespoke 3 axis CNC

machining systems for medical implant production.

He

consistently met the agreed targets for cost, quality and

timescales, and communicates progress well. We would have

struggled to make the progress that we did without him."

Tim Mead, Head of Product and Process Development,

OrthoMimetics Ltd.

|

|

Food

Processing and Packaging Food

Processing and Packaging

CTD has developed or modified large, fast moving automated

lines with a range of applications to :

- Heat, cook, boil

- Cool,

freeze

- Grip, spin, move

- Seal, unseal,

pierce

- Inspect, sense, measure

- Form, cross link

- Carbonate,

fill, pressurise

- Infuse, coat,

flavour

- Wash, sterilise

-

Transfer, dispense, meter, vend

- Package from web material

- Paper handle and fold |

|

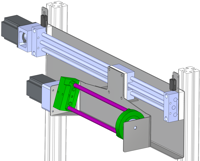

Driven

Spool with heated chemical bath, guided

recirculating flow and extrusion head. Driven

Spool with heated chemical bath, guided

recirculating flow and extrusion head.

"Oliver helped me to develop a complex automated assembly

system for production of novel biomaterials for use in

regenerative medicine. He demonstrated a high level of

technical ability in mechanical and electromechanical design

and was able to provide a highly responsive and adaptive

working style that enabled rapid progress to be made. In

addition, he anticipated our future requirements such that

we were able to rapidly translate concepts into lab-scale

prototypes and then into prototype production equipment;

this enabled a smooth transition through scale-up. I would

recommend Oliver as a highly skilled and pragmatic engineer

who can deliver high quality results to tight timelines."

Dr Simon Kew, Senior Scientist,

TiGenix Ltd.

|